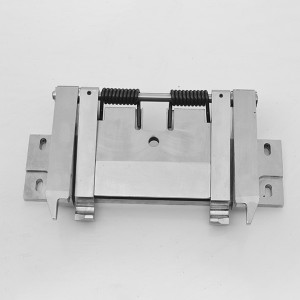

Tsarin hatimi

Stamping (wanda kuma aka sani da latsawa) shine tsarin sanya ƙarfe mai lebur a cikin ko dai babu komai ko coil form a cikin latsa mai tambari inda kayan aiki da saman saman ya mutu ke samar da ƙarfen zuwa siffa ta yanar gizo.Stamping ya haɗa da nau'ikan hanyoyin samar da takarda-karfe iri-iri, kamar naushi ta amfani da latsa na'ura ko buga latsawa, ɓalle, ƙwanƙwasa, lankwasa, flanging, da tsabar kuɗi.Wannan na iya zama aiki mataki guda ɗaya inda kowane bugun jini na latsa ya samar da fom ɗin da ake so akan ɓangaren karfen, ko kuma zai iya faruwa ta matakai daban-daban.Yawancin lokaci ana aiwatar da tsarin akan karfen takarda, amma kuma ana iya amfani dashi akan wasu kayan, kamar polystyrene.Mutuwar ci gaba yawanci ana ciyar da ita daga coil ɗin ƙarfe, na'urar na'ura don kwance na'urar zuwa madaidaicin don daidaita coil ɗin sannan a cikin mai ciyarwa wanda ke ciyar da kayan zuwa cikin latsa kuma ya mutu a ƙayyadadden tsawon ciyarwa.Dangane da rikitarwa na sashi, ana iya ƙayyade adadin tashoshi a cikin mutuwar.

Ana yin hatimi akan takardar ƙarfe mai sanyi.Duba Ƙarfafa don ƙirƙirar ayyukan ƙarfe masu zafi.

Bakin Karfe: SS304, SS304L, SS316, SS316L, SS303, SS630

Carbon karfe: 35CrMo, 42CrMo, ST-52, Ck45, gami karfe;ST-37, S235JR, C20, C45, 1213, 12L14 carbon karfe;

Garin Brass: C36000, C27400, C37000, CuZn36Pb3, CuZn39Pb1, CuZn39Pb2

Aluminum gami: AlCu4Mg1, AlMg0.7Si, AlMg1SiCu, EN AW-2024, EN AW-6061, EN AW-6063A.

1. Lankwasawa - kayan sun lalace ko lankwasa tare da madaidaiciyar layi.

2. Flanging - kayan yana lankwasa tare da layi mai lankwasa.

3. Embossing - kayan da aka shimfiɗa a cikin wani m ciki.Ana amfani da shi da farko don ƙara ƙirar kayan ado.

4. Blanking - an yanke wani yanki daga takarda na kayan, yawanci don yin komai don ƙarin aiki.

5. Tsabar kudi - ana matsawa ko matsi a cikin kayan.A al'adance ana amfani da su don yin tsabar kudi.

6. Zane - filin sararin samaniya yana shimfiɗawa zuwa wani nau'i na dabam ta hanyar sarrafa kayan aiki.

7. Ƙaddamarwa - filin sararin samaniya yana ƙaruwa ta hanyar tashin hankali, ba tare da motsi na ciki na gefen blank ba.Yawancin lokaci ana amfani da su don yin sassan jikin mota masu santsi.

8. Ironing - an matse kayan kuma an rage kauri tare da bangon tsaye.Ana amfani da gwangwani na abin sha da harsashi harsashi.

9. Ragewa / Necking - ana amfani dashi don rage diamita na ƙarshen buɗaɗɗen jirgin ruwa ko bututu.

10. Curling - abu mai lalacewa a cikin bayanan tubular.Ƙofar hinges misali ne na kowa.

11. Hemming - naɗe baki a kanta don ƙara kauri.Gefen ƙofofin mota galibi suna rufe.

Hakanan za'a iya yin huda da yanke a cikin matse tambari.Tambarin ci gaba shine haɗuwa da hanyoyin da ke sama da aka yi tare da saitin mutuwa a jere ta inda ɗigon kayan ya wuce mataki ɗaya a lokaci ɗaya.

Bakin sassa masu hatimi

Tsarin hatimi

Karfe sanyi stamping sassa