CNC niƙa tsari

Ikon lambobi (kuma sarrafa lambobi na kwamfuta, wanda aka fi sani da CNC) shine sarrafa sarrafa kayan aikin injina (kamar drills, lathes, mills da firintocin 3D) ta hanyar kwamfuta.Injin CNC yana aiwatar da wani yanki (karfe, filastik, itace, yumbu, ko hadawa) don saduwa da ƙayyadaddun ƙayyadaddun ƙayyadaddun umarnin da aka tsara kuma ba tare da ma'aikacin jagora yana sarrafa aikin injin kai tsaye ba.

Na'ura ta CNC kayan aiki ne mai motsi mai motsi kuma galibi dandamali ne mai motsi, wanda kwamfuta ke sarrafa su duka, bisa ga takamaiman umarnin shigarwa.Ana isar da umarni zuwa na'urar CNC a cikin nau'i na shirye-shiryen jeri na umarnin sarrafa injin kamar G-code da M-code, sannan a kashe su.Mutum na iya rubuta shirin ko kuma, sau da yawa, ya ƙirƙira shi ta hanyar software na ƙirar kwamfuta mai hoto (CAD) da/ko software na kera taimakon kwamfuta (CAM).Game da firintocin 3D, ɓangaren da za a buga an “yanke” ne, kafin a samar da umarni (ko shirin).Firintocin 3D kuma suna amfani da G-Code.

CNC babban ci gaba ne akan injinan da ba na kwamfuta ba wanda dole ne a sarrafa shi da hannu (misali ta amfani da na'urori kamar ƙafafun hannu ko levers) ko sarrafa injina ta jagororin ƙirar da aka riga aka kera (cams).A cikin tsarin CNC na zamani, ƙirar ɓangaren injina da shirin masana'anta na sarrafa kansa sosai.Ana bayyana ma'auni na injina ta hanyar amfani da software na CAD sannan a fassara shi cikin umarnin masana'anta ta software na masana'anta (CAM) mai taimakon kwamfuta.Ana canza umarnin da aka haifar (ta hanyar software na "post processor) zuwa takamaiman umarnin da ake buƙata don takamaiman na'ura don samar da sashin sannan a loda su cikin injin CNC.

Tun da kowane bangare na iya buƙatar yin amfani da kayan aiki daban-daban - ƙwanƙwasa, zato, da sauransu - na'urorin zamani sukan haɗa kayan aiki da yawa zuwa "kwayoyin halitta".A cikin wasu abubuwan shigarwa, ana amfani da nau'ikan injuna daban-daban tare da na'urar sarrafawa ta waje da na'ura mai sarrafa mutum ko na'ura mai ba da hanya tsakanin hanyoyin sadarwa waɗanda ke motsa kayan daga na'ura zuwa na'ura.A kowane hali, jerin matakan da ake buƙata don samar da kowane bangare na sarrafa kansa sosai kuma yana samar da wani ɓangaren da ya dace da ainihin zane na CAD.

Milling tsari ne na yankewa wanda ke amfani da abin yankan niƙa don cire abu daga saman yanki na aikin.Mai yankan niƙa kayan aikin yankan jujjuya ne, sau da yawa tare da maki yankan da yawa.Sabanin hakowa, inda kayan aiki ya ci gaba tare da juzu'in jujjuyawar sa, abin yanka a cikin niƙa yawanci ana motsa shi daidai da axis ta yadda yanke ya faru akan kewayen abin yanka.Yayin da mai yankan niƙa ya shiga cikin aikin, yankan gefuna (garwa ko haƙora) na kayan aiki akai-akai yankewa da fita daga kayan, aske guntu (swarf) daga aikin aikin tare da kowane fasinja.Ayyukan yankan shine lalacewa mai ƙarfi;Ana fitar da kayan aiki a cikin ƙananan ƙullun da ke rataye tare zuwa babba ko ƙarami (dangane da kayan) don samar da kwakwalwan kwamfuta.Wannan ya sa yankan ƙarfe ya ɗan bambanta (a cikin injiniyoyinsa) daga yankan abubuwa masu laushi da ruwa.

Tsarin niƙa yana cire kayan ta hanyar aiwatar da daban-daban, ƙananan yanke.Ana samun wannan ta hanyar yin amfani da abin yanka mai hakora da yawa, jujjuya abin yankan da sauri, ko ciyar da kayan ta cikin mai yankan a hankali;Mafi yawan lokuta shi ne wasu hade da wadannan hanyoyi guda uku[2].Gudun gudu da ciyarwar da ake amfani da su sun bambanta don dacewa da haɗakar masu canji.Gudun da yanki ya ci gaba ta wurin abin yanka ana kiransa ƙimar abinci, ko kawai ciyarwa;galibi ana auna shi a matsayin nisa a kowane lokaci (inci a cikin minti daya [in/min ko ipm] ko millimeters a minti daya [mm/min]), kodayake ana amfani da nisa kowane juyi ko kowane haƙori a wasu lokuta.

Akwai manyan nau'ikan nau'ikan niƙa guda biyu:

1.A fuska milling, da yankan mataki faruwa da farko a ƙarshen sasanninta na milling abun yanka.Ana amfani da niƙa fuska don yanke filaye (fuskõki) a cikin aikin, ko don yanke ramukan ƙasa.

2.In na gefe milling, da yankan mataki faruwa da farko tare da kewaye da abun yanka, sabõda haka, giciye sashe na milled surface ƙare har samun siffar da abun yanka.A wannan yanayin ana iya ganin ruwan wukake na yankan a matsayin kwashe kayan aiki daga aikin.Niƙa na gefe ya dace da yankan ramummuka masu zurfi, zaren, da haƙoran gear.

| Injin CNC | Bayani |

| Mill | Fassara shirye-shiryen da suka ƙunshi takamaiman lambobi da haruffa don matsar da igiya (ko kayan aiki) zuwa wurare da zurfafa daban-daban.Yawancin suna amfani da lambar G.Ayyuka sun haɗa da: niƙa fuska, niƙa kafada, taɗawa, hakowa da wasu ma suna ba da juyawa.A yau, injinan CNC na iya samun gatura 3 zuwa 6.Yawancin injinan CNC suna buƙatar sanya kayan aikin akan ko a ciki kuma dole ne su kasance aƙalla girman girman aikin, amma ana samar da sabbin injunan axis 3 waɗanda suka fi ƙanƙanta. |

| Lathe | Yanke kayan aiki yayin da ake juya su.Yana yin sauri, daidaitaccen yanke, gabaɗaya yana amfani da kayan aikin da za'a iya ƙididdigewa da rawar jiki.Ingantattun shirye-shirye masu rikitarwa da aka ƙera don yin sassan da ba za su yuwu a yi su akan lathes na hannu ba.Irin ƙayyadaddun bayanai na sarrafawa zuwa injinan CNC kuma galibi suna iya karanta lambar G.Gabaɗaya suna da gatari guda biyu (X da Z), amma sabbin samfura suna da ƙarin gatari, suna ba da damar ƙarin ayyuka na ci gaba don injina. |

| Plasma abun yanka | Ya haɗa da yanke abu ta amfani da fitilar plasma.Yawanci ana amfani da su don yanke karfe da sauran karafa, amma ana iya amfani da su akan abubuwa iri-iri.A cikin wannan tsari, ana hura iskar gas (kamar matsewar iska) da sauri daga bututun ƙarfe;a lokaci guda kuma, ana samun baka na lantarki ta wannan gas daga bututun ruwa zuwa saman da ake yankewa, yana mai da wasu daga cikin wannan gas din zuwa plasma.Plasma yayi zafi sosai don narkar da kayan da ake yanke kuma yana motsawa da sauri don busa narkakkar karfe daga yanke. |

| Injin fitar da wutar lantarki | (EDM), wanda kuma aka sani da walƙiya machining, tartsatsin tartsatsin wuta, konewa, mutuwa nutse, ko wayoyi ya zazzage, tsari ne na masana'anta wanda ake samun siffar da ake so ta hanyar amfani da wutar lantarki.Ana cire kayan aiki daga kayan aiki ta jerin fitattun fitattun abubuwan da ke faruwa a yanzu tsakanin na'urorin lantarki guda biyu, wanda ruwan dielectric ya rabu kuma yana ƙarƙashin wutar lantarki.Daya daga cikin na'urorin da ake kira da Tool Electrode, ko kuma kawai "kayan aiki" ko "electrode," yayin da dayan ake kira workpiece electrode, ko "workpiece". |

| Na'ura mai yawa spindle | Nau'in na'urar dunƙule da ake amfani da shi wajen samar da taro.An yi la'akari da inganci sosai ta hanyar haɓaka aiki ta atomatik.Za a iya yanka kayan cikin ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun yayin amfani da nau'ikan kayan aiki iri-iri.Nau'o'in spindle masu yawa suna da sanduna da yawa a kan ganga da ke juyawa akan axis a kwance ko a tsaye.Drum din yana dauke da kai mai dunƙulewa wanda ya ƙunshi ɗimbin dunƙulewa waɗanda aka ɗora a kan ƙwalƙwalwar ƙwallo kuma ana sarrafa su da kayan aiki.Akwai nau'ikan haɗe-haɗe guda biyu don waɗannan shugabannin haƙoran, ƙayyadaddun ko daidaitacce, dangane da ko tsakiyar nisa na igiya mai hakowa yana buƙatar bambanta. |

| Farashin EDM | Har ila yau, an san shi da yankan waya EDM, waya kona EDM, ko EDM mai tafiya waya, wannan tsari yana amfani da zaizayar wuta zuwa na'ura ko cire abu daga duk wani abu na lantarki, ta amfani da na'urar lantarki mai tafiya.Wutar lantarki ta waya yawanci tana ƙunshe da kayan tagulla- ko zinc mai rufi.Wire EDM yana ba da damar kusa da kusurwoyi na 90-digiri kuma yana amfani da matsa lamba kaɗan akan kayan.Tun da wayar ta lalace a cikin wannan tsari, na'urar EDM na waya tana ciyar da sabon waya daga spool yayin da ake sare wayar da aka yi amfani da ita kuma a bar ta a cikin kwandon shara don sake amfani da ita. |

| Farashin EDM | Har ila yau ana kiran nau'in cavity EDM ko girma EDM, mai sinker EDM ya ƙunshi na'urar lantarki da kayan aiki wanda aka nutsar da shi cikin mai ko wani ruwa mai dielectric.Ana haɗa wutar lantarki da kayan aiki zuwa wutar lantarki mai dacewa, wanda ke haifar da yuwuwar wutar lantarki tsakanin sassan biyu.Yayin da na'urar ta ke gabatowa wurin aikin, raguwar dielectric yana faruwa a cikin ruwan da ke samar da tashar plasma da ƙananan tartsatsin tsalle.Samuwar ya mutu kuma ana yin gyare-gyare sau da yawa tare da sinker EDM.Wasu kayan, irin su kayan ferrite masu laushi da kayan magnetic mai-arziƙin haɗaɗɗiya ba su dace da sinker EDM ba saboda ba su da wutar lantarki.[6] |

| Mai yankan ruwa | Har ila yau, an san shi da "waterjet", kayan aiki ne da ke iya yankawa cikin karfe ko wasu kayan (kamar granite) ta hanyar amfani da jet na ruwa a cikin sauri da matsa lamba, ko cakuda ruwa da wani abu mai lalacewa, kamar yashi.Ana amfani da shi sau da yawa yayin ƙirƙira ko kera sassa don injuna da sauran na'urori.Waterjet ita ce hanyar da aka fi so lokacin da kayan da ake yankewa ke kula da yanayin zafi da wasu hanyoyin ke haifarwa.Ya samo aikace-aikace a cikin nau'o'in masana'antu daban-daban daga hakar ma'adinai zuwa sararin samaniya inda ake amfani da su don ayyuka kamar yanke, sassaƙa, sassaƙa, da reaming. |

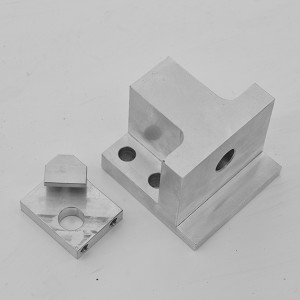

Farashin CNC

sassa

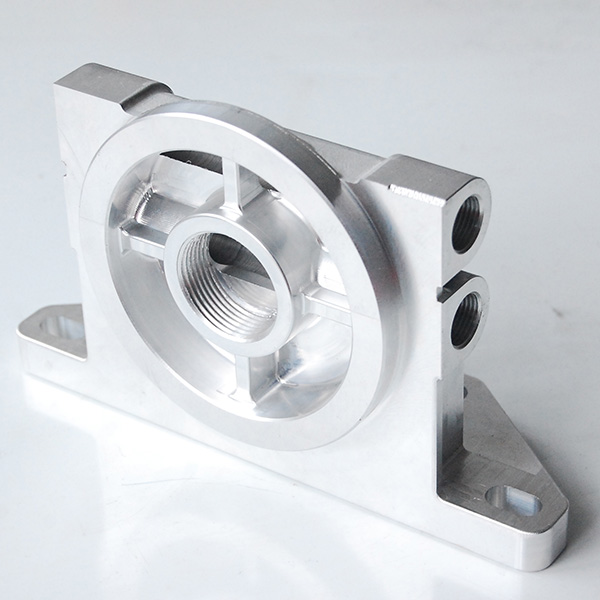

Injin CNC

sassan aluminum

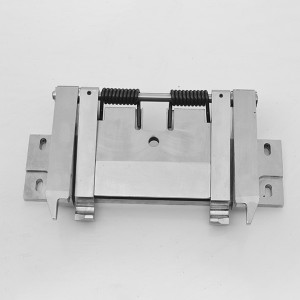

Injin CNC

lankwasawa sassa

CNC machining sassa

tare da anodizing

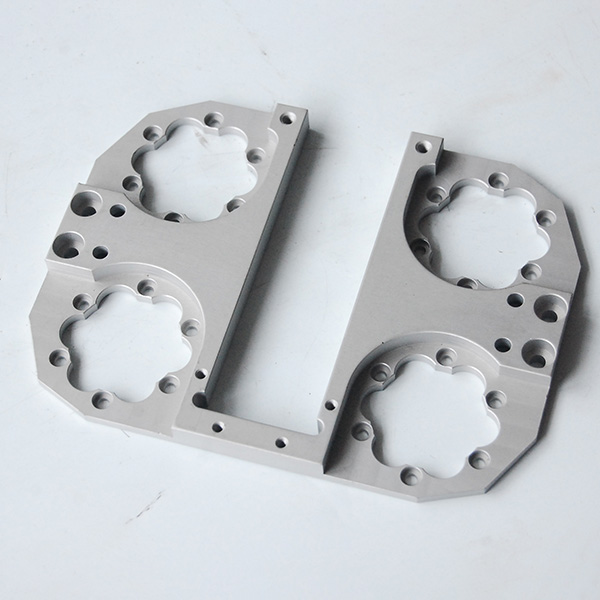

Babban daidaito

sassan cnc

Daidaitaccen simintin gyare-gyaren aluminum

tare da machined da anodized

Daidaitaccen simintin aluminum

tare da injina

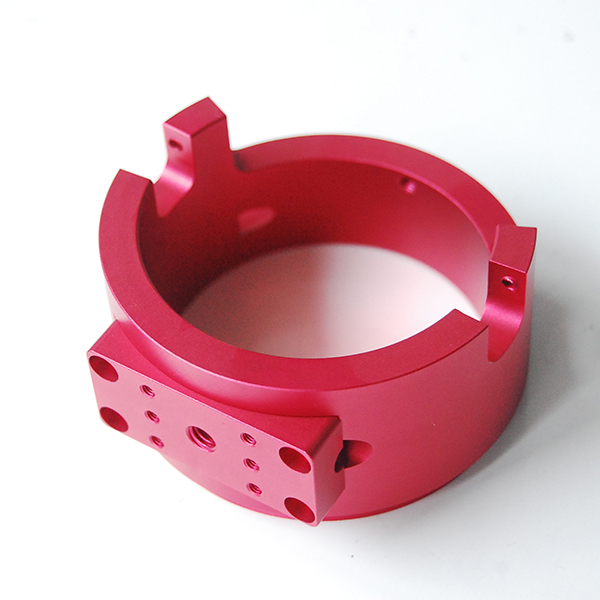

Karfe cnc

machining sassa