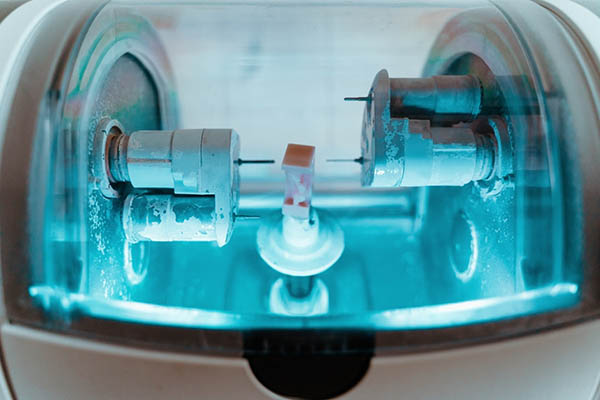

Daga cikin hanyoyin samar da ƙarfe da yawa waɗanda masana'antun zamani ke amfani da su, fineblanking yana ɗaya daga cikin hanyoyin musamman waɗanda ke haɗa fasahar stamping da extrusion sanyi.Ɗaya daga cikin dalilan da ya sa wannan hanya ta tashi sama da matsayi shine tana iya samar da sassa masu rikitarwa waɗanda sauran hanyoyin yin tambari ba su iya yi.Koyaya, gudummawar mashin ɗin daidaitaccen mashin don fineblanking yana da mahimmanci.Yana amfani da matsi da kayan aiki na musamman don samar da takamaiman ɓangaren da abokin ciniki ke buƙata.A yau yana da wuya a sami sabis na injin injin CNC mai kyau kuma abin dogaro.

Muhimmancin fineblanking

A cikin shekarun da suka wuce, masana'antun sun so su haɗu da ma'auni na ma'auni tare da wani fasaha wanda zai iya samar da mafi tsabta da gefuna ko da menene zane.Zuwan fineblanking ya amfanar da masu fasaha saboda yanayin wannan tsarin yanke yana buƙatar daidaitaccen kayan aiki.Masu kera suna tabbatar da cewa sun yi amfani da sabbin kayan aikin daidai don su iya samun sakamakon da ake so yayin da suke yin fineblanking.Wannan tsari yana barin kaɗan ko babu hutu kwata-kwata.

Idan aka kwatanta da sauran hanyoyin yankan da ke da hannu a masana'anta samfur, fineblanking ta hanyar mashin daidaici yana barin sassan yanar gizo na bakin ciki bayan yanke.Har ila yau, yawancin abokan ciniki suna buƙatar mafi girman yankewa a cikin masana'antu, kuma hakan yana yiwuwa ne kawai ta hanyar fineblanking.Suna ba da kwanciyar hankali na musamman saboda daidaitattun kayan aikin da aka yi amfani da su.Haka kuma, sigar 2D tana ba da ƙaramin murdiya.Wannan yana ba da mafi m yanke fiye da abin da ka iya gani har yanzu.

Me yasa madaidaicin mashin ɗin ke da mahimmanci don daidaitaccen fineblanking

Babban fa'idar fineblanking akan sauran hanyoyin yankan ana yin shi a cikin aiki ɗaya.Yana daya daga cikin hanyoyin da suka fi dacewa da tsada, kuma masana'antun na iya amfani da shi akan nau'ikan karafa don samar da sassan da ake buƙata ta nau'i daban-daban.Daidaitaccen mashin ɗin yana taka muhimmiyar rawa a cikin wannan hanyar saboda kayan aikin suna ba da mafi kyawun ma'auni ta yadda mai fasaha zai iya yanke ainihin ƙirar da abokin ciniki ke so.Fitowar ita ce daidai kamar yadda abokin ciniki ya ƙayyade.Tun da komai yana faruwa a mataki guda ɗaya, zaku iya ajiyewa akan ƙarin farashin aiki kamar niƙa, aski, broaching, niƙa, da reaming.

Ana ba da wasu mahimman fasalulluka na fineblanking a ƙasa:

● Fineblanking yana ba da ƙaƙƙarfan flatness na ƙarfe.Har ila yau, yana inganta iyawar samar da matakan juriya ga na'ura.

● Za su iya buga ramuka a cikin kewayon kauri na 60% daga gefen.Sakamakon ramukan na iya zama ƙanana kamar kauri na kayan.

●Mafi ƙanƙanta na mutuwa yana jujjuyawa zuwa gefe.Mafi ƙarancin hutun mutuwa yana adana ɗimbin kuɗi a cikin dogon lokaci.

Fineblanking idan sau da yawa ana amfani da shi akan flanges, watsawa, sarrafa ruwa, da wuraren da ke jikin abin hawa.Abubuwan ƙira masu rikitarwa na waɗannan sassa suna buƙatar haɗuwa da daidaituwa da tsarin yankan santsi wanda aka samu ta hanyar mashin daidaitaccen mashin da fineblanking.

Akwai yuwuwar samun wasu hanyoyin yankan da yawa, amma babu wanda yake da tasiri kamar fineblanking.Ba wai kawai mafita mai tsada ba ne ga masana'anta amma kuma yana adana lokaci, kuma yana ba da ainihin ƙirar ƙarfe wanda abokin ciniki yake so.ƙwararrun ƙwararrun ƙwararrun ƙwararrun galibi ba sa son bin wasu fasahohin yanke saboda fa'idodin da fineblanking ke ba su.

Lokacin aikawa: Yuli-30-2021